MPCNC Size Calculator¶

Sizing¶

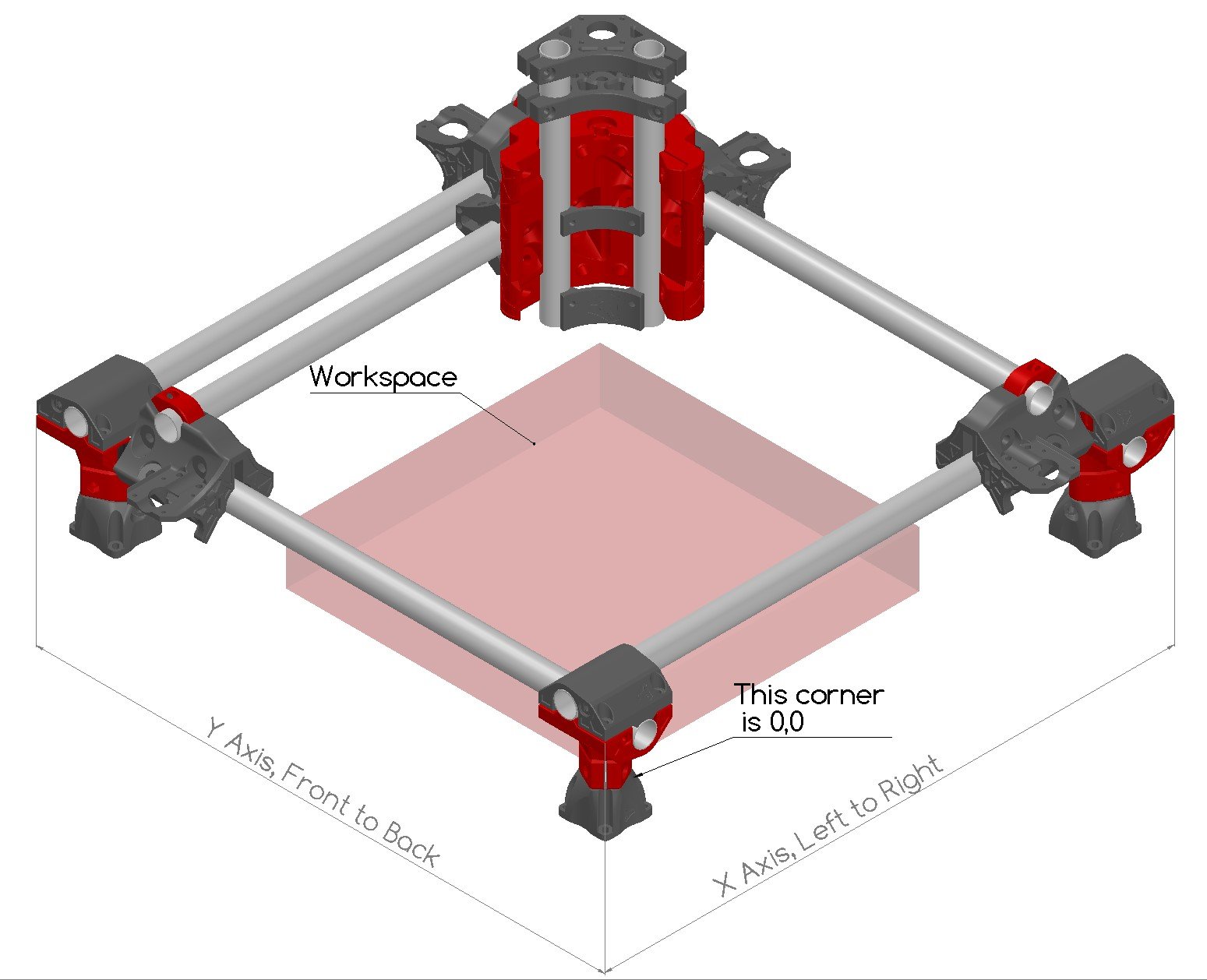

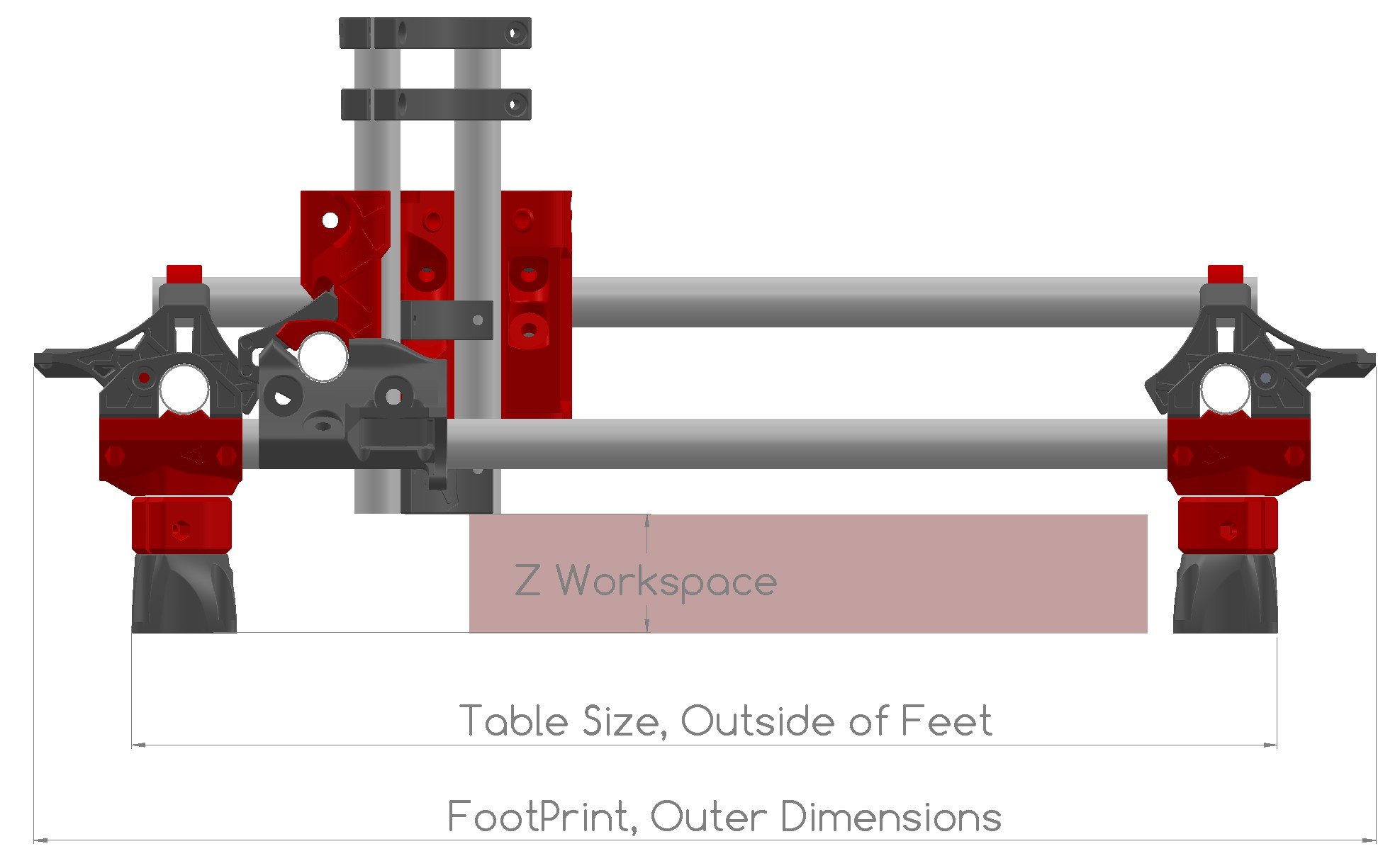

When choosing what size to make your machine, start with the build area. This is the area your tool can reach. Smaller machines are more rigid. The more rigid a machine is, the easier and more forgiving it is to use. This gives you a larger acceptable feeds and speeds window. More rigid also means it will be faster and more accurate with the right settings. Every millimeter counts but the Z axis has the largest effect on rigidity. For a Primo MPCNC, 81mm is the shortest and I highly recommend that. More sizing details on this page.

Inputs¶

Units¶

Metric (mm)

Imperial (inch)

Model¶

Primo

Burly

Tool Choice *¶

Full range of motion (pen, laser, drag knife, Makita RT70x, etc)

Dewalt DW660

52mm & 55mm Spindle

* Tool Choice

Larger tools may collide with the side rails and restrict movement before the MPCNC reaches its full range of motion in X and Y. Select your intended tool to account for this difference in the following dimensions:

Size Calculator¶

Workspace¶

mm x

mm y

mm z

Tube Lengths¶

| Length (mm) | Qty | Name |

|---|---|---|

| 2 | x rails, sides | |

| 1 | x rail, gantry | |

| 2 | y rails, sides | |

| 1 | y rail, gantry | |

| 2 | z rails | |

| 4 | legs | |

| total needed | total tube length assuming 3mm kerf |

Material Dimensions¶

| Length (mm) | Qty | Name |

|---|---|---|

| 1 | leadscrew length | |

| 2 | belt length along x | |

| 2 | belt length along y | |

| total length | belts (all 4) |

Table Size¶

| Length (mm) | Name |

|---|---|

| x table size (outer edges of feet) | |

| y table size (outer edges of feet) |

Total Machine Footprint¶

| Length (mm) | Name |

|---|---|

| x | |

| y | |

| z | |

| clearance to remove z axis |