SKR Pro V1.1 & V1.2¶

Basics¶

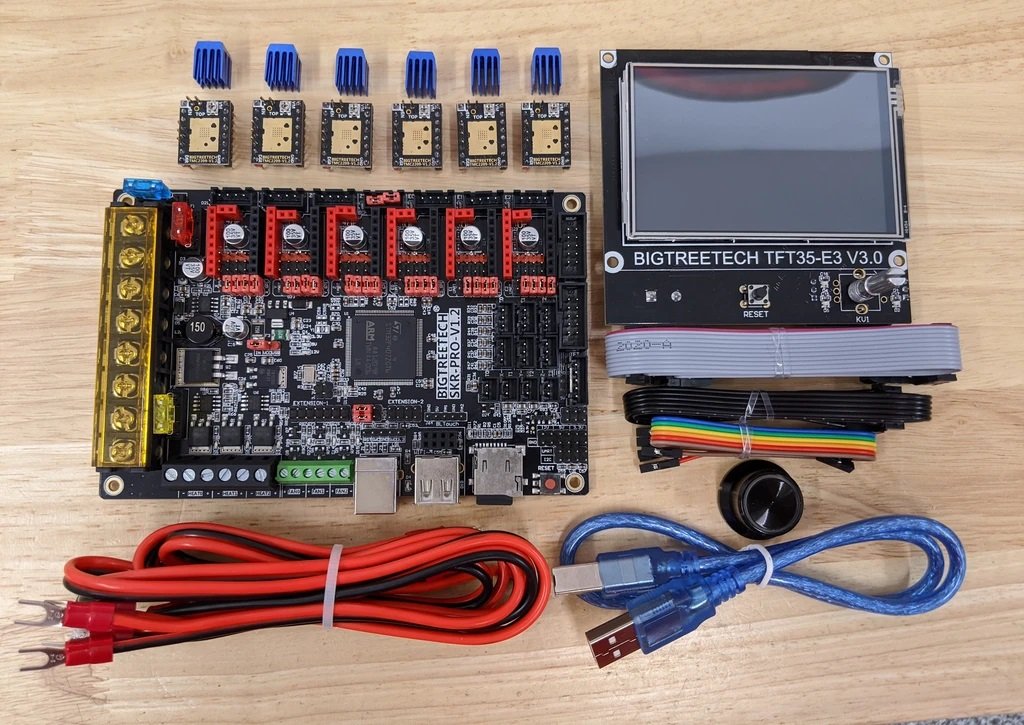

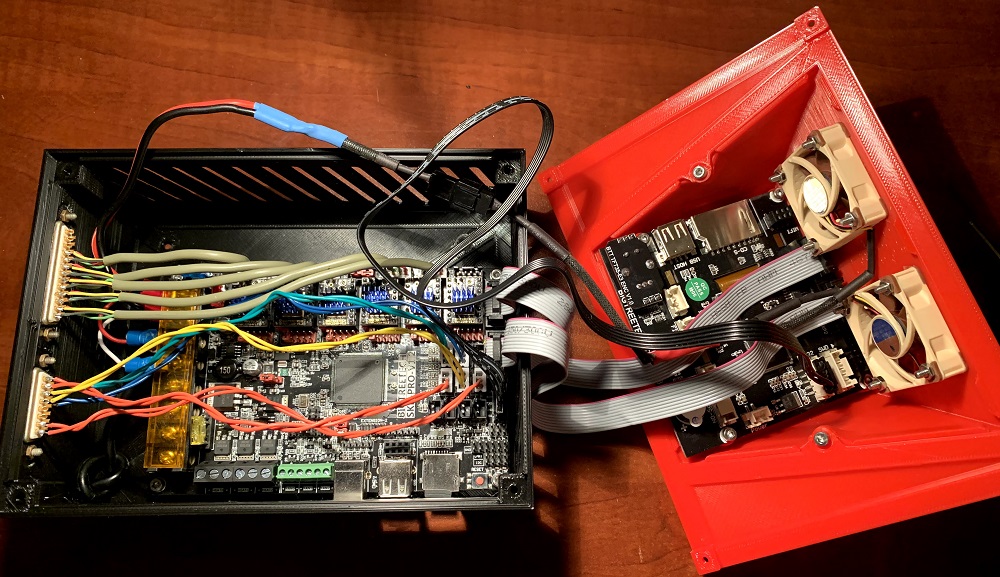

The SKR Pro is a 32bit 6 driver board with 6 easily controllable ports running at 12-24V. Beyond the basics there are loads of extra pins, options for two different power supplies at two different voltages, WiFi Ports, future expansion port for USB, and the Trinamic TMC drivers with digital current control.

Want to Buy one?

SKR Pro Bundle is available here in the shop.

There are many options involved here. To offer the best experience for most users I have settled on the TMC2209 drivers, and the TFT35 V3 E3 screen.

2209

The Trinamic 2209 V1.2 drivers offer UART communication for dynamic control, 2A RMS with a 2.8A peak. We will be operating far under these values. The Trinamic drivers have many advanced features. For a CNC Machine, the main features we use are digital current control and dynamically lowering the hold current so we can also keep stepper and driver heat down while operating at slightly higher than usual stepper power!

Setup¶

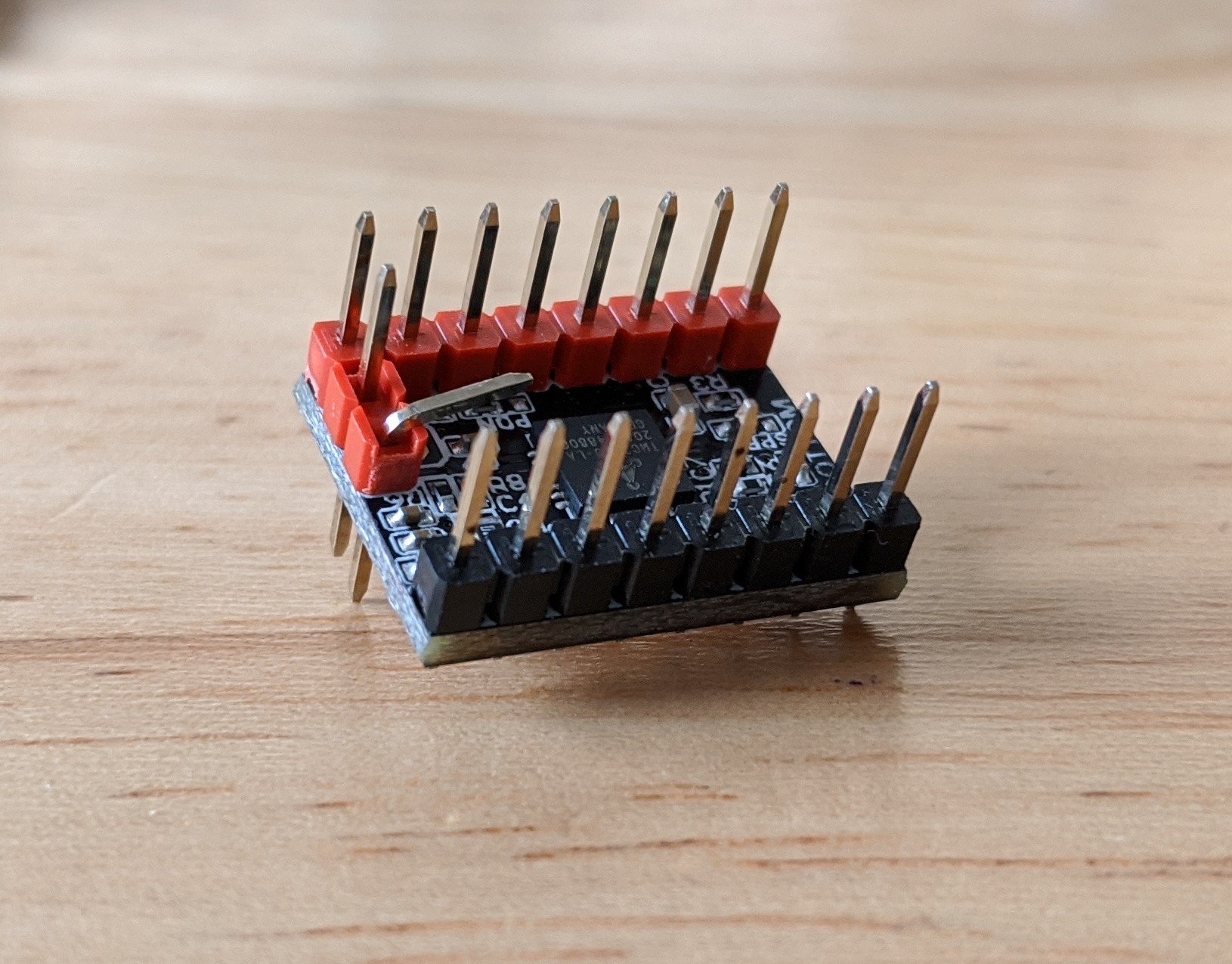

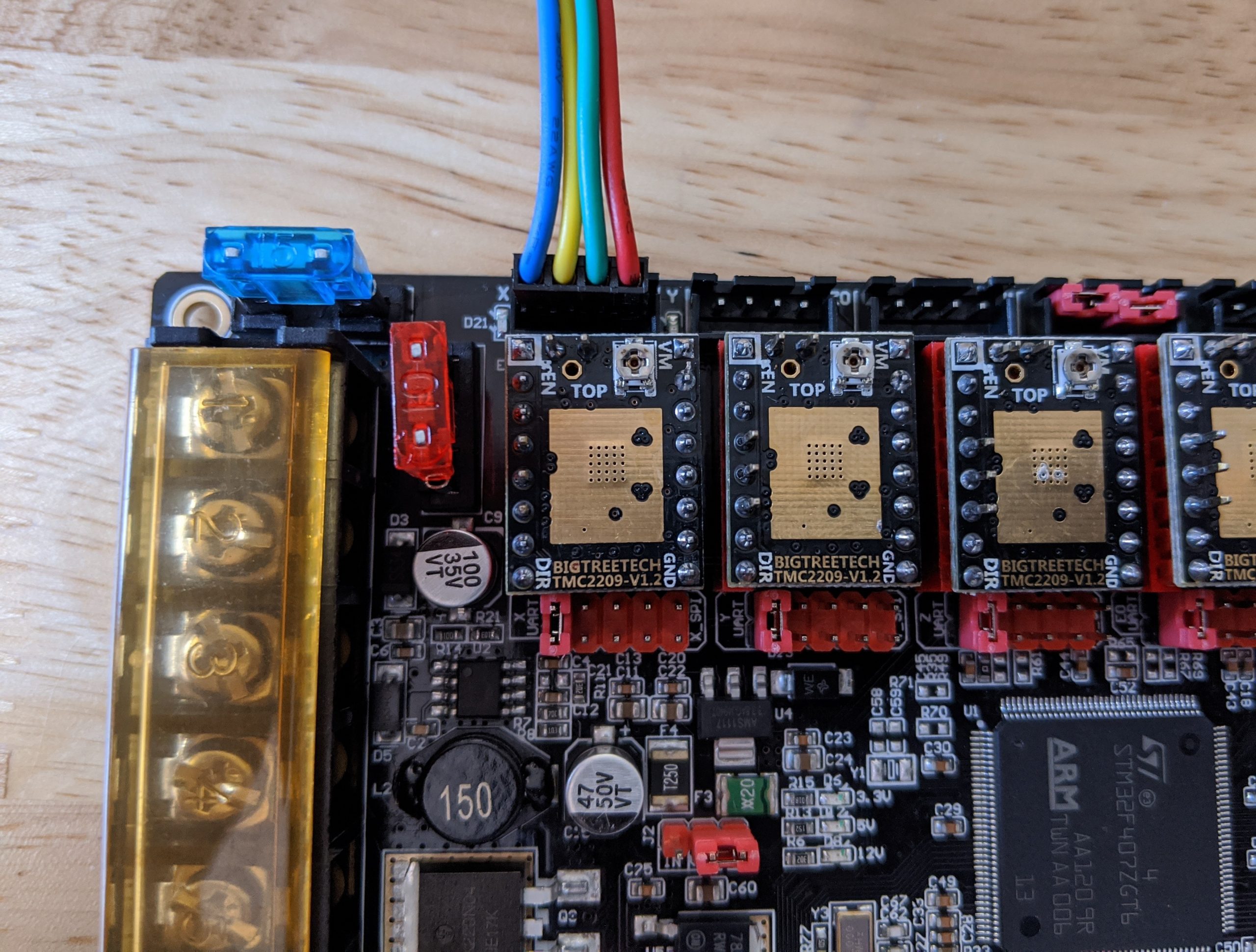

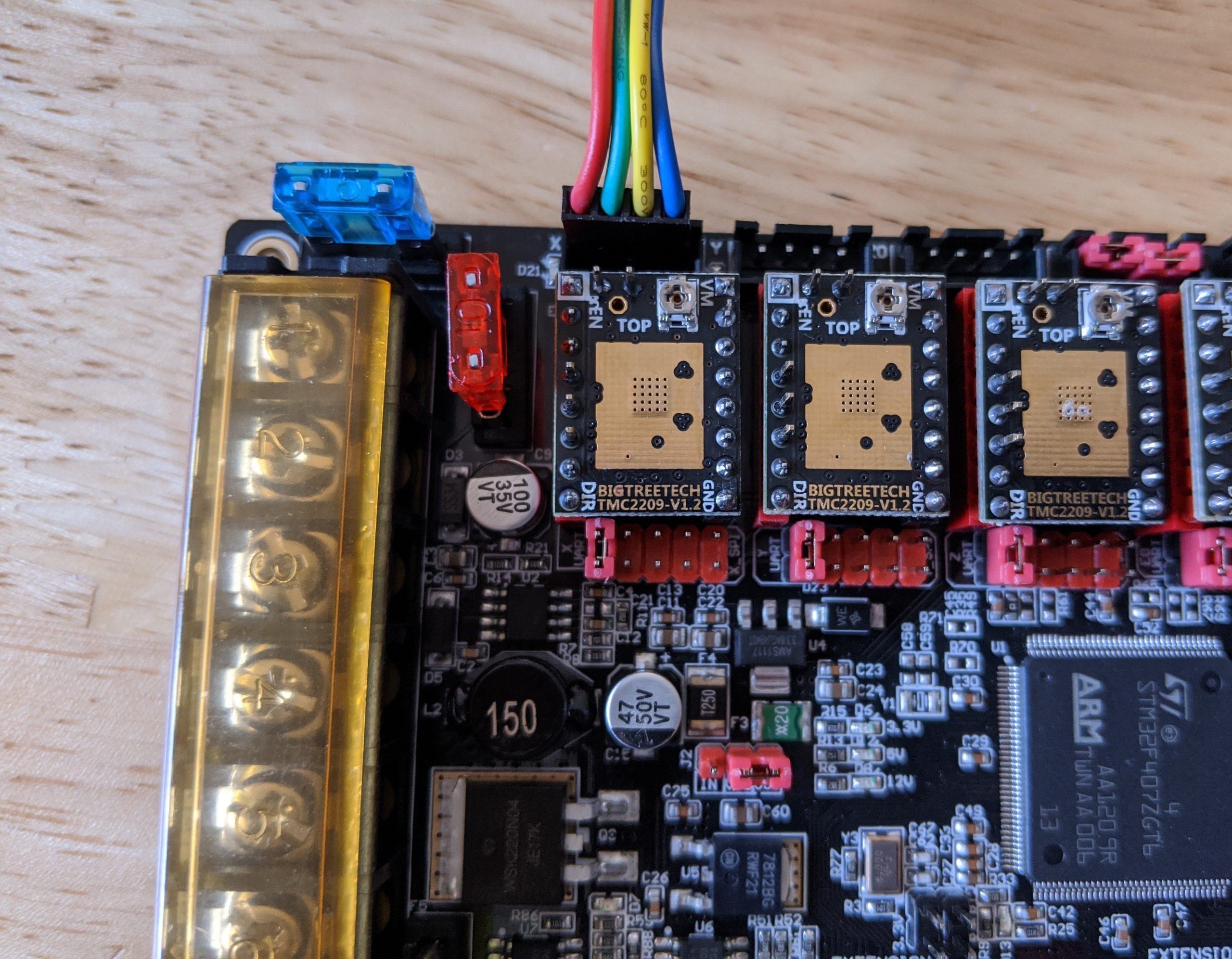

Disable Sensorless Pin¶

Sensorless homing is not as accurate as mechanical end stops. All the pre-compiled firmware has this disabled so you will need to bend the pins out of the way.

Bend this pin on each driver to allow mechanical switches to be used on the SKR board.

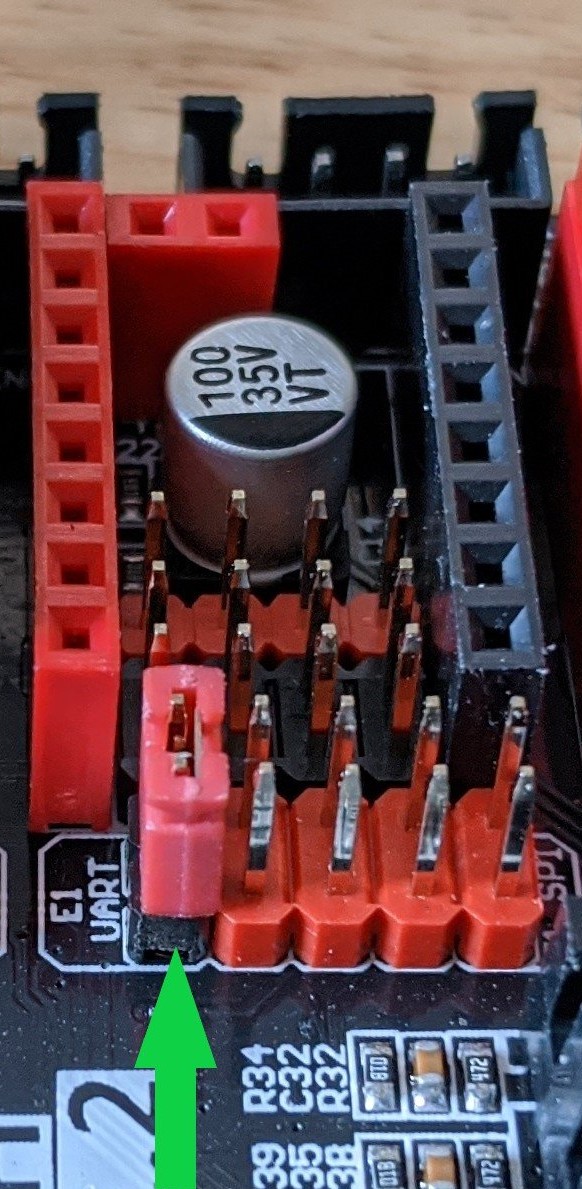

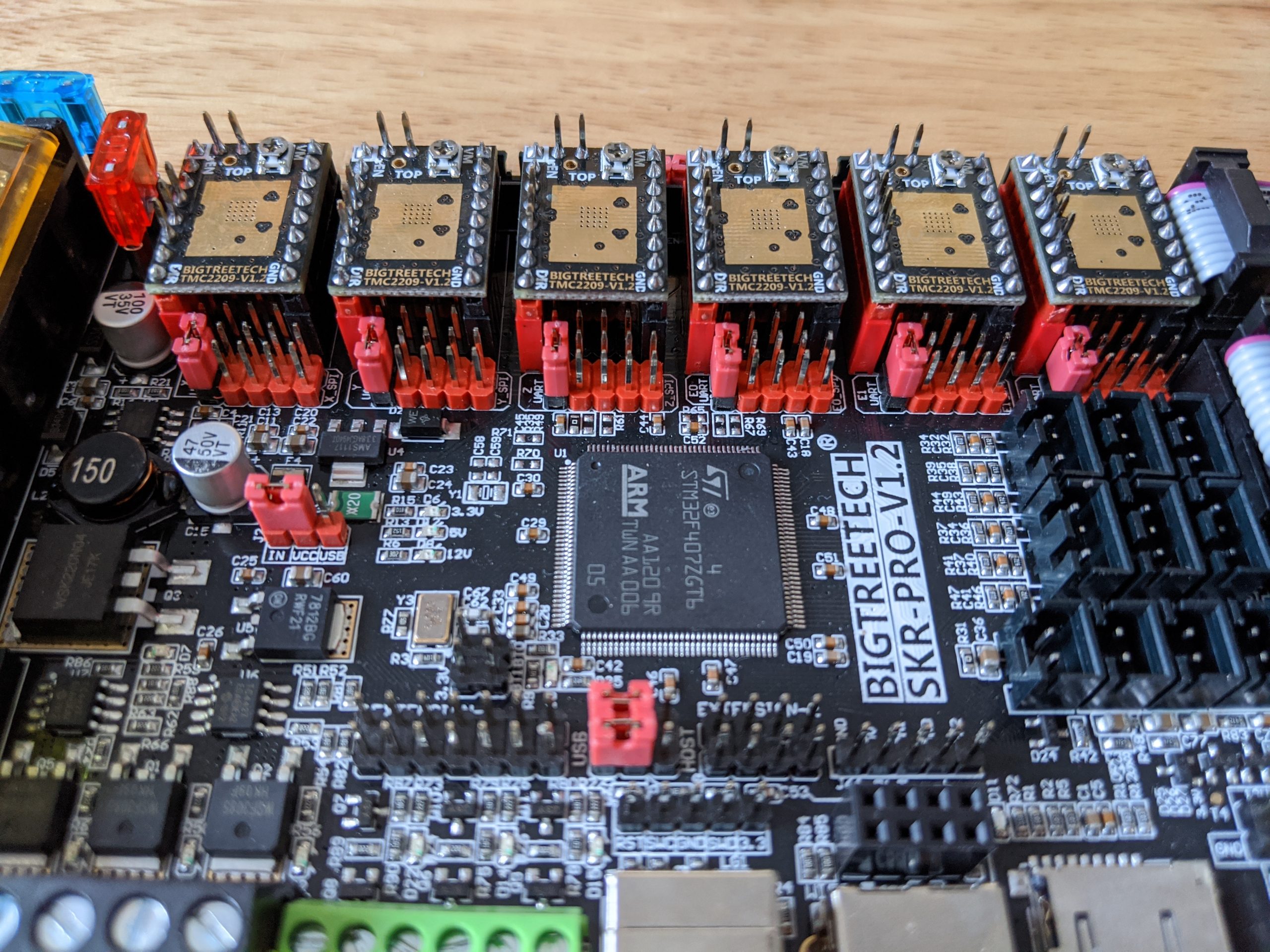

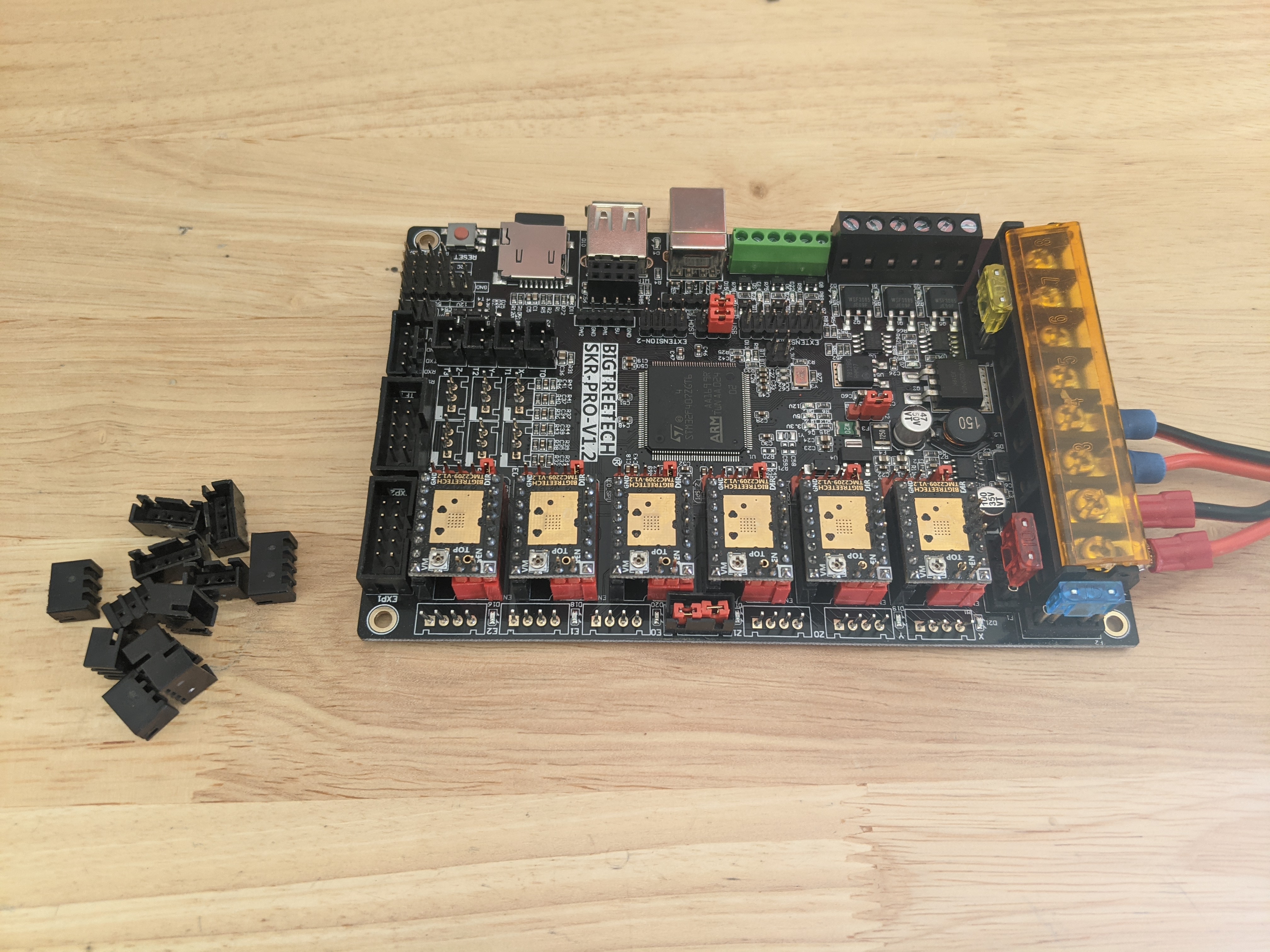

Jumpers¶

For the firmware to be able to control the current and receive feedback from each driver the board needs to be set for UART communication. To do this you remove the 4 jumpers from each port and place one jumper on the black (UART) pins. There is no need to monkey with the tiny potentiometers!

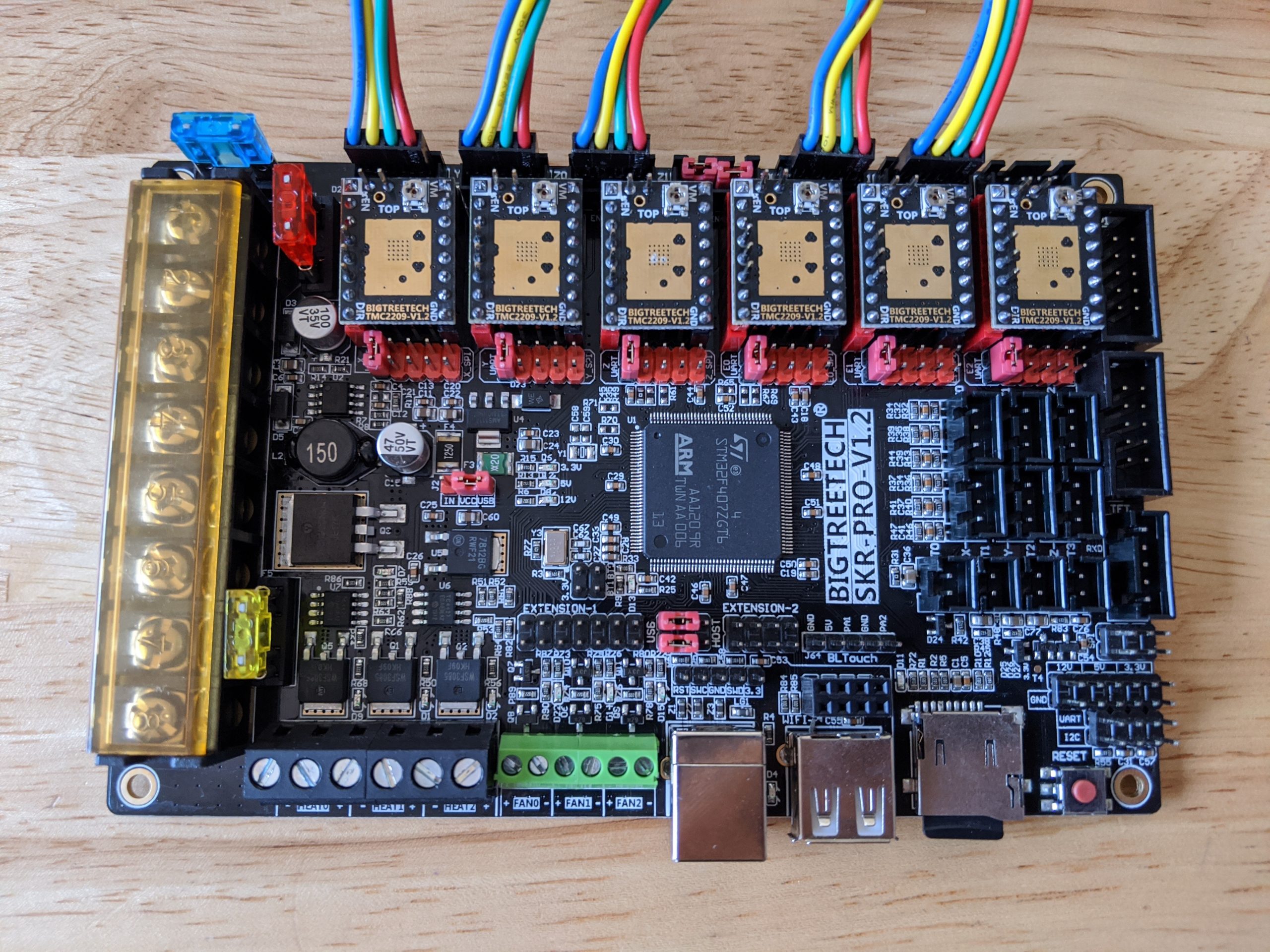

The completed board looks like this. Notice there are no jumpers under the drivers. Lowrider and MPCNC builds will have only 5 drivers, MP3DP uses 6.

At this point you can add the heat sinks being careful not to short any of the pins and only stick them to the copper pads centered on the top.

Molex and JST connectors¶

The current V1 Engineering wiring kits have the Molex style terminations on them. The SKR Pro is the first board to be offered with JST directional style connections. To keep the stepper direction easy to change a pretty easy solution is just pulling off the JST plastic shields. The pin spacing is the same and pulling the shields off make for a more solid connection to the Molex style wires we used. Needle nosed pliers and a little wiggling make this pretty easy.

Depending on what wires you are plugging in you can take them off the end stops and stepper ports. Even after doing this you should always constrain your wires directly after the connection to the board to prevent them from wiggling loose.

Wiring Steppers¶

We have a few options for how the steppers get connected to this board. Here are the three most common ways we might use it.

MPCNC and LowRider CNC¶

MPCNC

| Board Label | Stepper Wire |

|---|---|

| X | X1 |

| Y | Y1 |

| Z0 | Z |

| Z1 | Jumpers stay in place |

| E0 | X2 |

| E1 | Y2 |

LowRider CNC

| Board Label | Stepper Wire |

|---|---|

| X | X |

| Y | Y1 |

| Z0 | Z1 |

| Z1 | Jumpers stay in place |

| E0 | Y2 |

| E1 | Z2 |

Reversing a stepper¶

If your stepper is moving the wrong way you can power down, unplug the power, and flip the stepper plug over to change the direction of rotation.

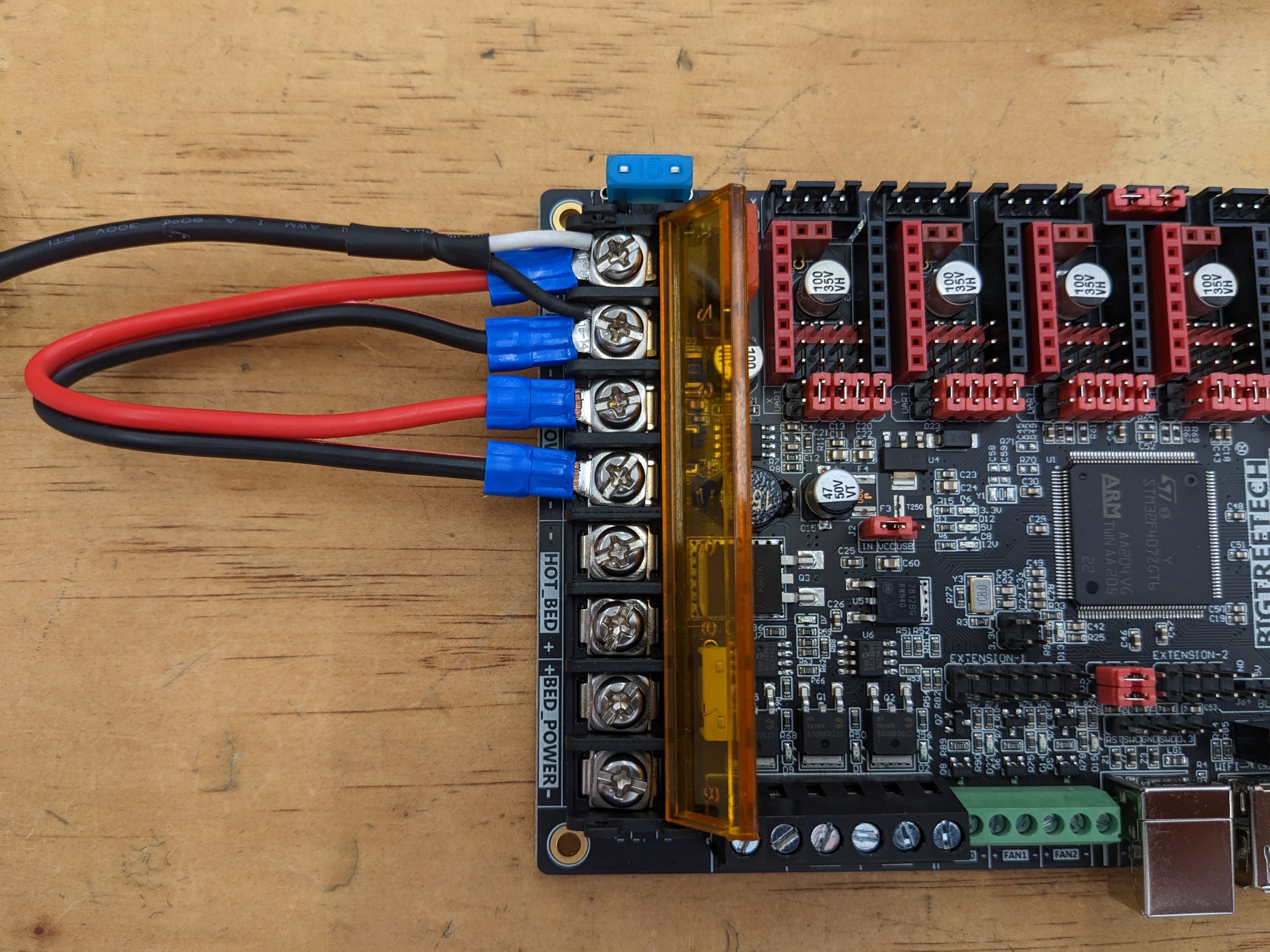

Powering the board¶

Add the power supply, polarity matters, and then add a jumper to power both “motor pow” and “power ports”.

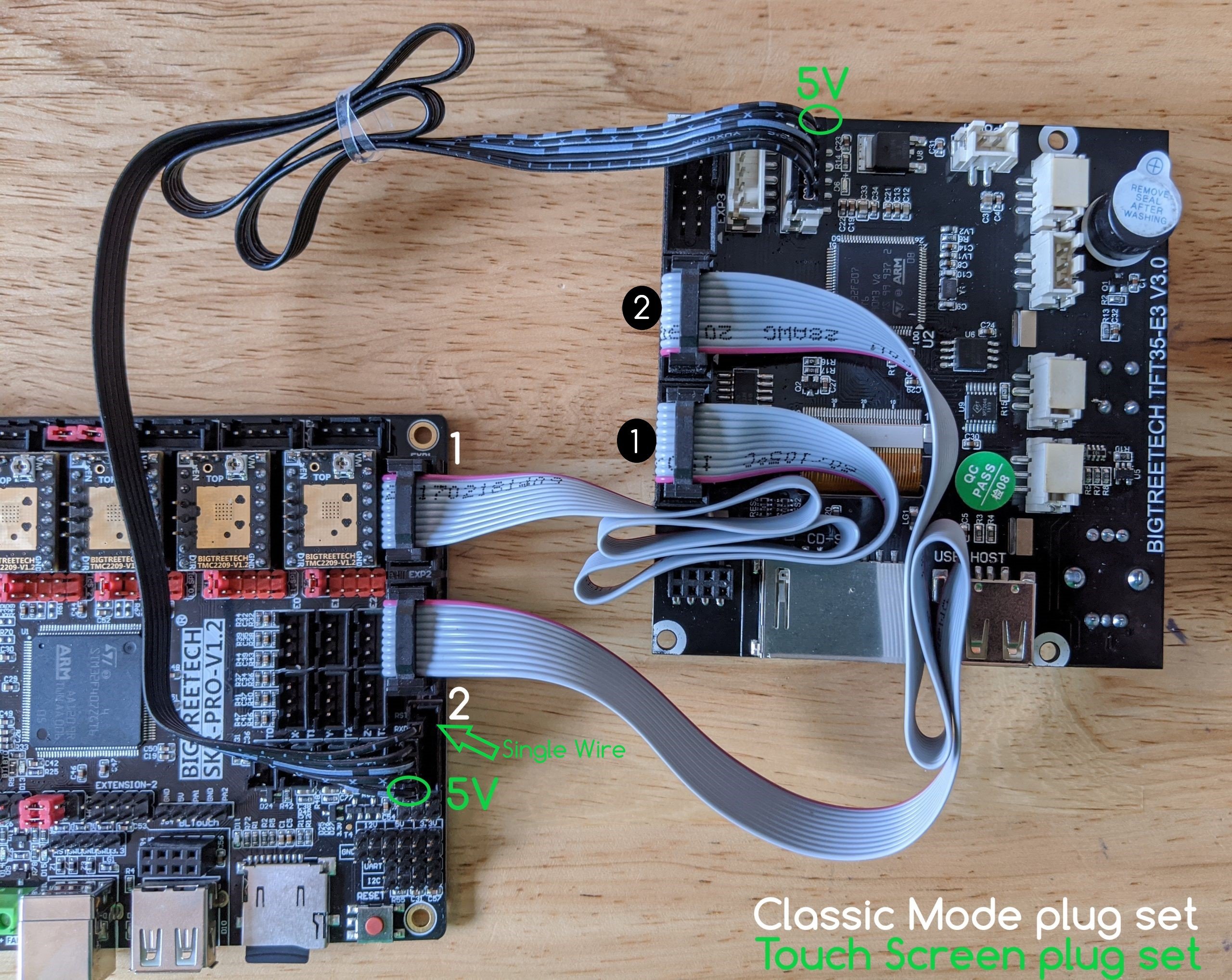

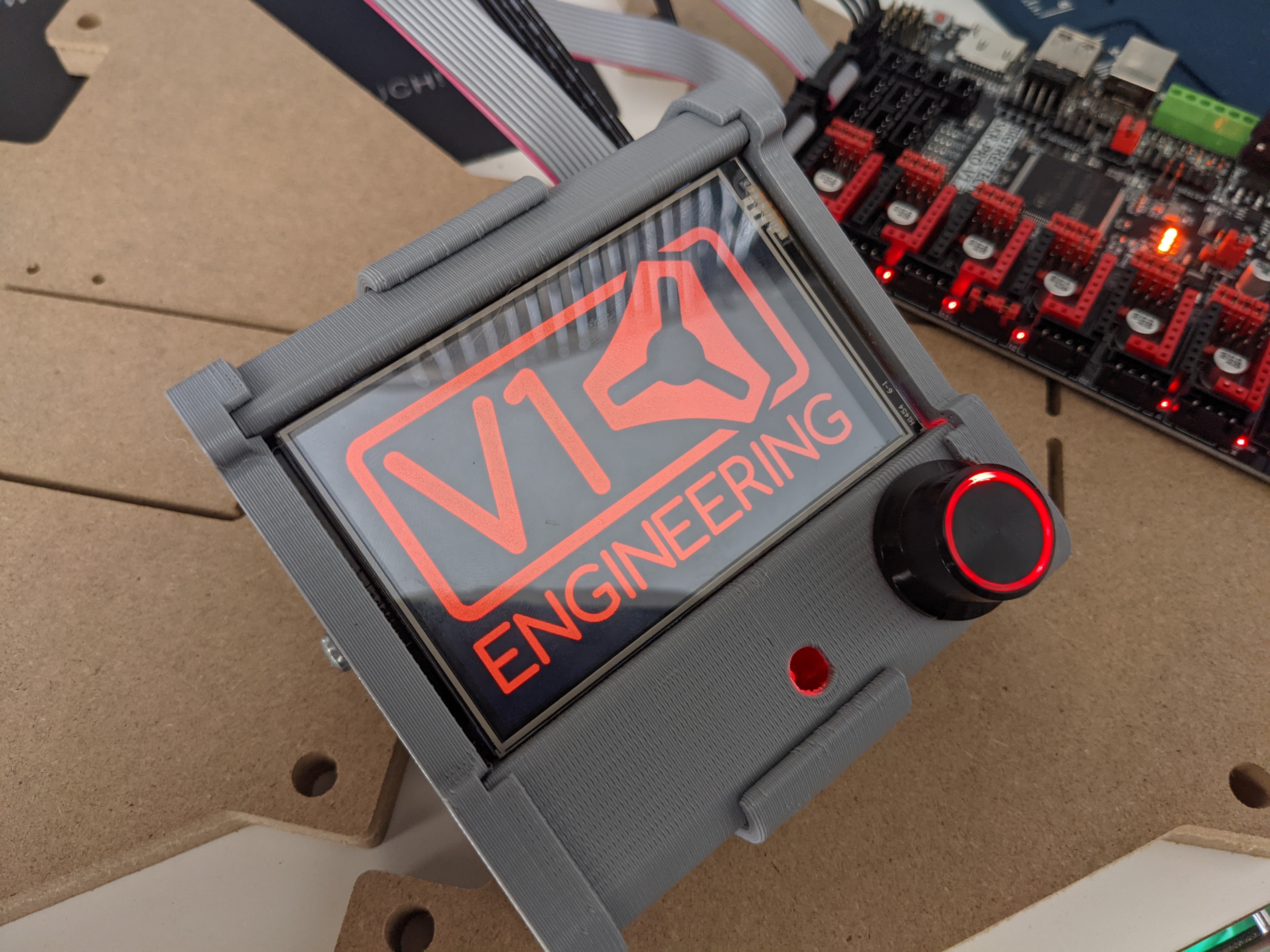

Screen TFT35 V3 E3¶

We can use it from both Touchscreen mode and Classic mode, simultaneously. Switching between modes is as easy as pressing the knob in for 3 seconds.

You do not need to use both; pay attention to the direction the wires are facing when connecting them.

You

Pay attention to the direction the wires are facing when connecting

them. The single wire faces toward the drivers, 5V closest to the memory card.

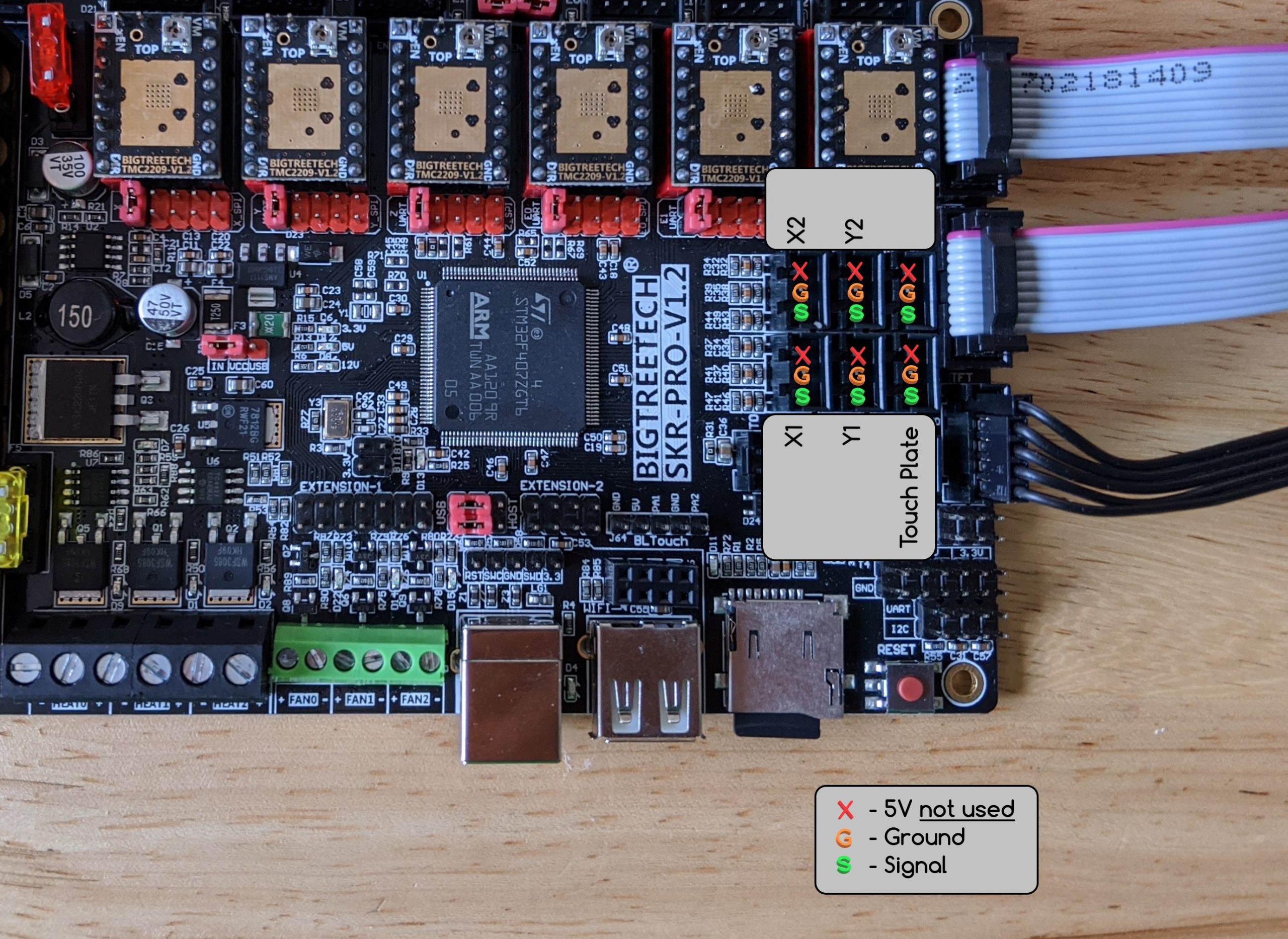

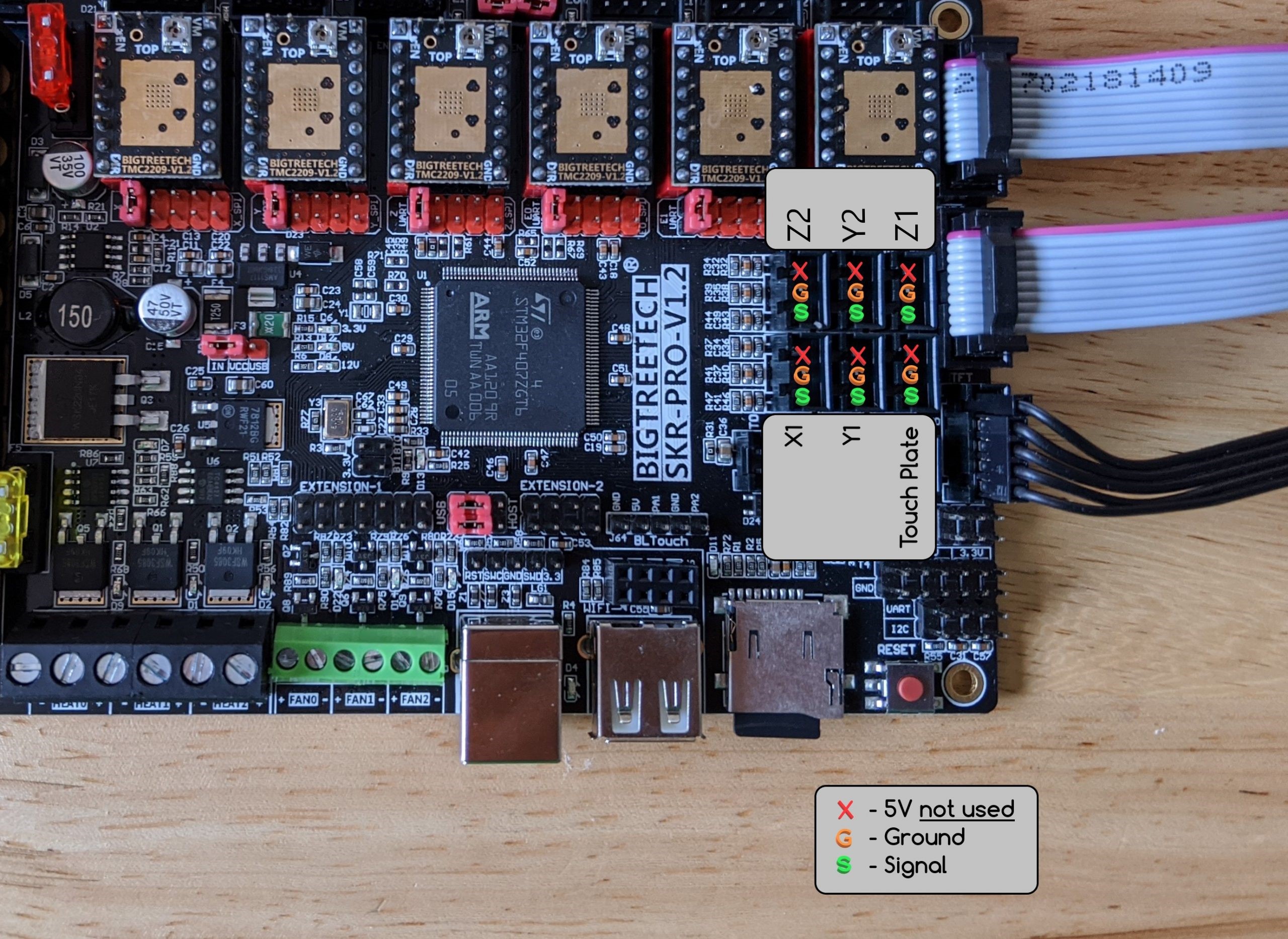

Touch plate¶

All the V1 firmware is ready for a touch plate. Easy as plugging into the Z min port. Use Ground “G” and Signal “S” pins, they are labeled on the back of the board.

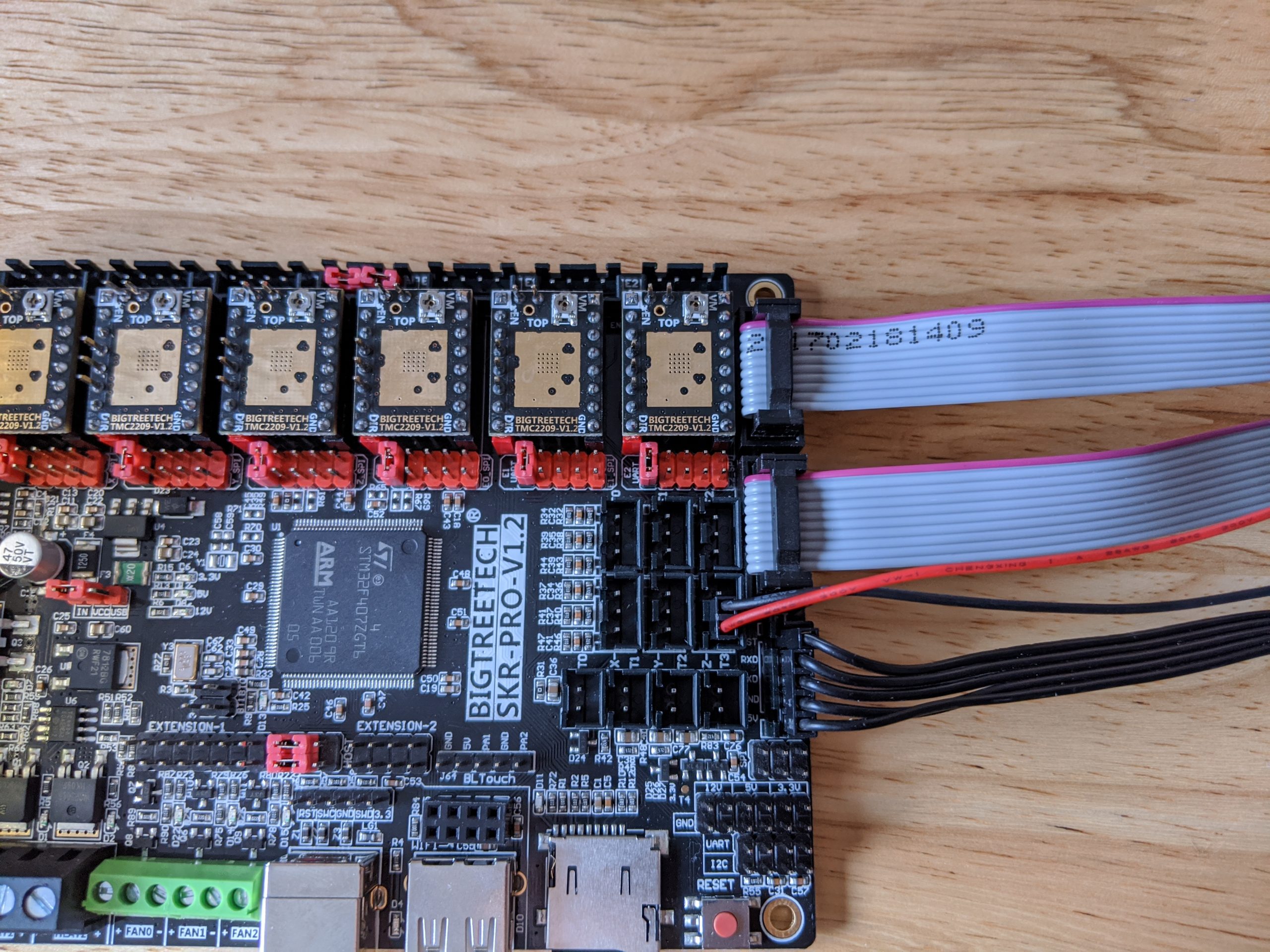

Dual End Stops, End Stops¶

If you are running the Current firmware you will need to have your endstops wired in Normally Closed (NC), this is the outer two tabs on the endstops, we do not use the middle one. You will plug into the Signal and Ground pins, Do not use the + pins. Use Ground “G” and Signal “S” pins, they are labeled on the back of the board.

Optical endstops are not recommended on a machine used for milling or routing. The debris can inhibit their function.

Troubleshooting

There is a known issue on SKR Pro1.2 boards where a small percentage of boards intermittently do not trigger a stop in the firmware. The technical reason is the on board circuit was designed with a voltage divider that is on the edge of the microprocessors HIGH/LOW signal limit. This results in random missing of the stop signal. A symtom of this is that one or more of the steppers keep driving after the limit switch triggers. You will find the stop LEDs on the SKR board will illuminate, but the firmware does not react. This is discussed in this thread There are a few ways to address this: 1) Replace the SKR board. 2) Solder 1.5K ohm resistors on the bottom of the board. 3) Modify the end stop wires to add the 1.5K ohm resistor.

MPCNC Dual Endstops¶

LowRider Dual endstops¶

Note

Do not use the + (positive) pins or you will ruin your SKR Pro board. Unless you are running a different project with powered endstops.

Firmware¶

The SKR Pro and TFT screen both can use a bin file to re-flash the firmware. This is as simple as placing some files directly on the memory card and rebooting them. The boards come already flashed from the store. This would only be used if you want to update.

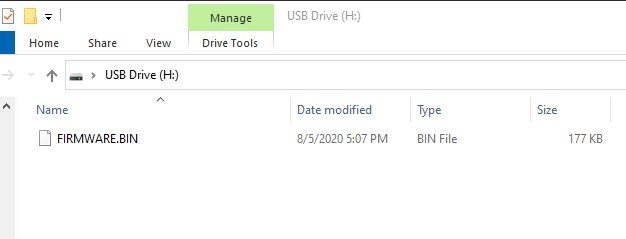

SKR Bin¶

You have options of firmware for the exact board, driver, screen package as sold in the V1 store.

- V1CNC_SkrPro_Dual_2209-** Ready for dual end stops on an MPCNC (X & Y axes).

- V1CNC_SkrPro_DualLR_2209-** Ready for dual end stops on a LowRider CNC (Y & Z axes).

-

- V1CNC_SkrPro_2209-** Ready for series wiring on any CNC build.

When you unzip the file you have a .bin file. Rename to FIRMWARE.bin and save it to the MicroSD for the SKR Pro board. Make sure to unplug both grey exp½ cables for the screen before proceeding. With the power off, insert the MicroSD into the control board, power on, and the board will flash a few green LED’s for a few seconds. The board now has new firmware (seriously that easy).

Remove the Micro SD card, after flashing

Note

Do not use a SKR Pro based machine with the microSD card in the SKR Pro board unless you are using the headless module. This seems to cause random performance issues otherwise.

The file will change extensions when a successful flash happens.

Current release bin files, V1 Engineering pre-configured firmware.

You also have the option to get the full Marlin source and edit and compile yourself using Platformio Docs.

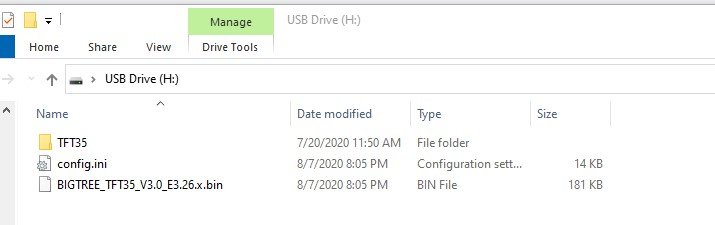

TFT Files¶

Flashing the screen takes a .bin file, the config file, and usually the TFT35 folder (unzipped) on the root of the screens SD card.

BIGTREE_TFT35_V3.0_E3.**.bin config.ini TFT35 (folder)

Now reset the screen (or board) and watch the screen update itself. You can double check and the files will have a new extension after a successful flash.

The V1 Engineering CNC version of the TFT firmware is on this page, use the most recent and the files can be had under the assets drop down - TFT Firmware

TFT Touch reset¶

If you somehow mess up the touch calibration placing and empty reset.txt file on the card and resetting will trigger a re-calibration.

Compile your own (source)¶

If you want to make any changes you will need to compile form the source files using Platform.io. Here is a basic walk through, Platformio Docs.

The V1 Engineering version of the SKR Pro firmware can be found on github, there are two versions, series and MPCNC dual endstop.

The V1 Engineering generic version of the TFT firmware is in this GitHub repo

Cases¶

TFT35 E3 V3 Case¶

Box for the TFT35 E3 V3.

Flyfisher604 SKR Pro v1.2 and TFT E3 v3.0 Case¶

A three-part case (lower box, top lid, and sloped TFT screen) that includes:

- Ventilation on two sides of the lower box

- Two fan mounts with integrated grates on the back of the sloped TFT screen

- Built in standoffs for the SKR Pro board and TFT screen

- Opening on TFT sloped screen mount exposing the SD card slot

- Openings for DB25 and DB15 connectors (with mounting screw holes) to interface internal wiring to MPCNC (or use these as pass throughs)

Available here on Thingiverse.